Stacker airtable

An electric stacker is an industrial vehicle powered by a battery and driven by an electric motor. It is primarily used for lifting, stacking, and short-distance transportation of goods. It is widely used in warehouses, workshops, logistics centers, ports, and other scenarios. It can efficiently complete vertical stacking of goods from the ground to shelves (with the highest stacking height reaching several meters) and horizontal transfer. It is a key piece of equipment to replace traditional manual stacking and improve the utilization of storage space.

Key Features

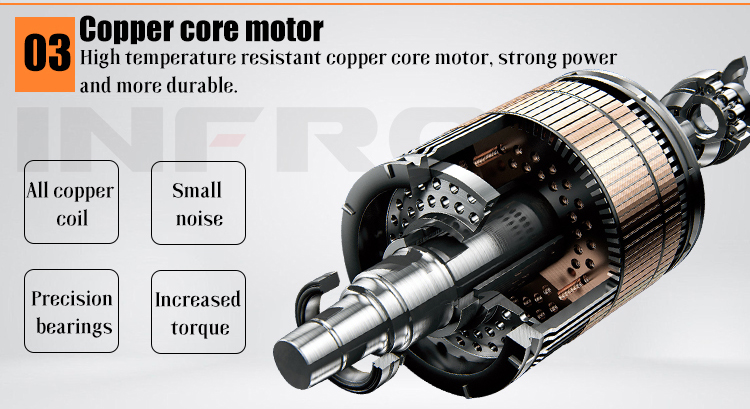

1. Brushless AC drive motor, maintenance-free, reducing maintenance costs.

2. Vertical drive motor makes inspection and maintenance more convenient, and its performance is significantly better than horizontal motors.

3. Integrated microswitch design allows for easy replacement.

4. Easy-to-open battery cover for adding distilled water or electrolyte.

5. Displays hourly time and battery status, reminding the operator to recharge the battery promptly.

6. Controller self-diagnostic system simplifies troubleshooting.

Details display

The Stacker Airtable is flexible and efficient, easily handling material handling in a variety of scenarios.

✅ 1. Compact Structure, Flexible Maneuverability

The stacker's compact size and tight turning radius make it ideal for maneuvering in narrow aisles, between shelves, or in otherwise confined spaces. It easily handles short-distance handling and low- to medium-level stacking of palletized goods, significantly improving space utilization.

✅ 2. Easy Operation, Quick Learning

Both manual hydraulic and electric stackers offer simple and intuitive operation. Electric stackers feature one-touch lift and slow start and stop functions. No license is required, allowing employees to quickly take up the helm with minimal training, reducing training costs.

✅ 3. Low Cost, Quick Return on Investment

Compared to forklifts, stackers offer lower procurement costs and simpler maintenance, eliminating the need for complex upkeep. They are particularly suitable for small and medium-sized businesses and startup warehouses, enabling mechanized handling within a limited budget and rapidly improving operational efficiency.

✅ 4. Multiple Types to Meet Different Needs

Manual Stackers: Economical and practical, suitable for light-load, low-frequency operations such as supermarket restocking and small warehouse sorting.

Semi-Electric Stackers: Electric lift + manual travel reduces labor intensity and improves stacking efficiency.

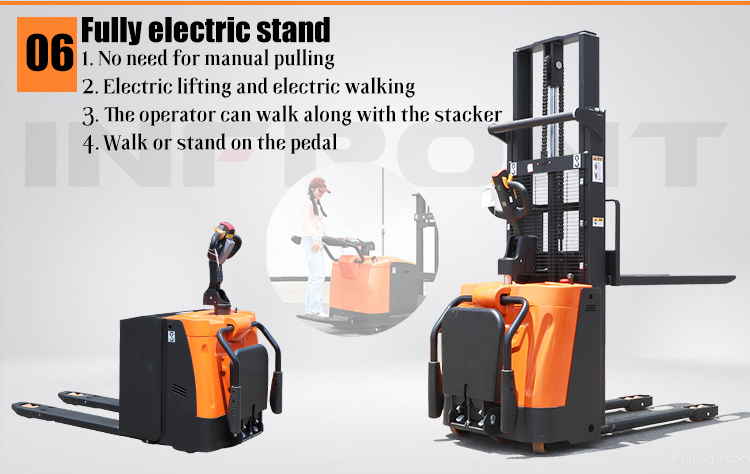

Fully Electric Stackers: Fully electric drive with integrated lift and travel control, suitable for high-frequency, medium-to-high-load operations. Operate from either a stand-up or sit-down position, with strong continuous operation capabilities.