Multiple excavator accessories have arrived at the overseas warehouse, and the inventory of shovel teeth has been fully upgraded.

As the demands for construction efficiency and equipment reliability in small-scale engineering projects continue to rise, the importance of excavator accessories in actual construction is becoming increasingly prominent. To further improve our localized service system in overseas markets and help customers more efficiently meet the needs of different working conditions, our US overseas warehouse recently completed the centralized warehousing and inventory upgrade of a batch of mini excavator shovel teeth and side teeth accessories.

The shovel teeth products that arrived this time are mainly compatible with 0.8-ton to 1.8-ton mini excavator buckets, covering the current mainstream small-tonnage excavator application needs in the overseas market, and are suitable for various construction scenarios such as earthmoving, municipal engineering, landscaping, and infrastructure construction.

Starting with the materials: High-manganese steel for highly wear-resistant bucket teeth

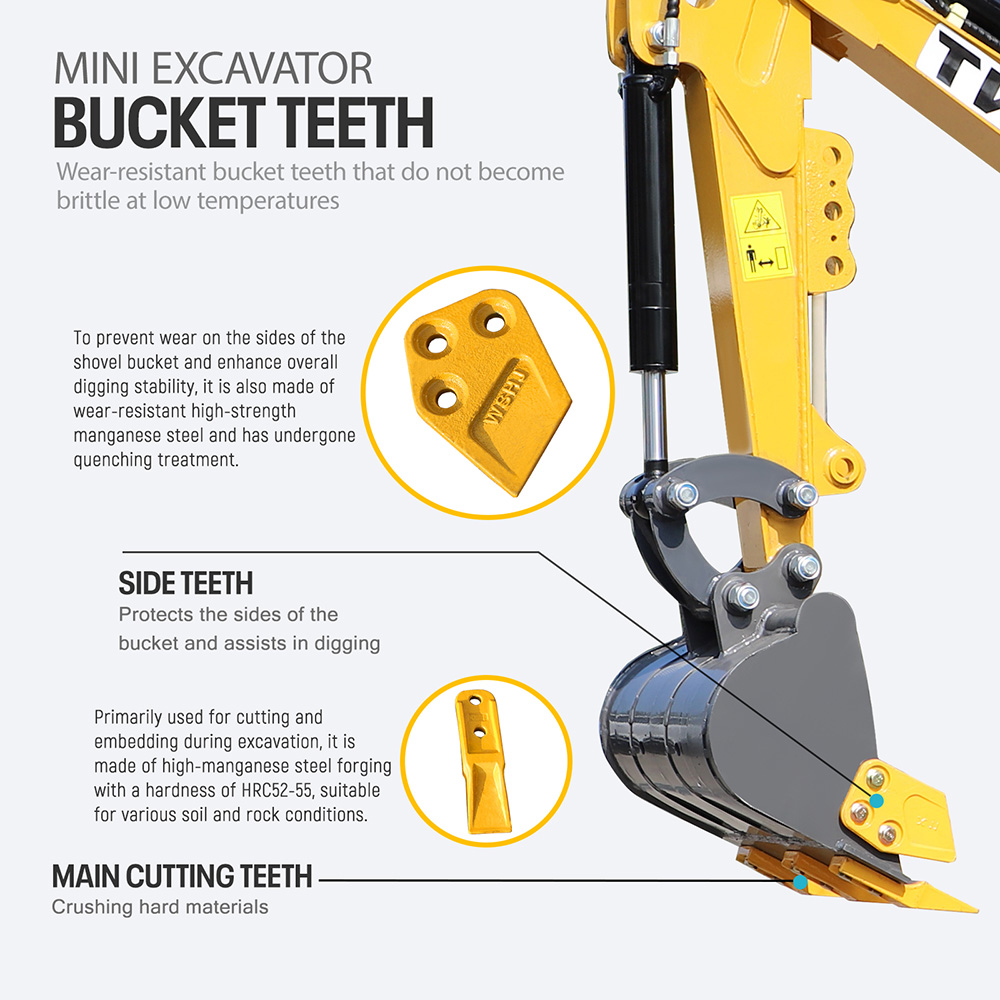

In excavation operations, bucket teeth are high-frequency consumable components, and their wear resistance and stability directly affect the overall machine's operating efficiency and maintenance costs. This batch of overseas warehouse bucket teeth uses high-strength, wear-resistant manganese steel as the core material, which has significant advantages over ordinary materials in terms of impact resistance, wear resistance, and service life.

Especially in low-temperature construction environments, ordinary material bucket teeth are prone to brittleness and breakage, while high-manganese steel has better toughness, maintaining stable structural strength even in cold regions or winter construction conditions, avoiding material embrittlement caused by low temperatures.

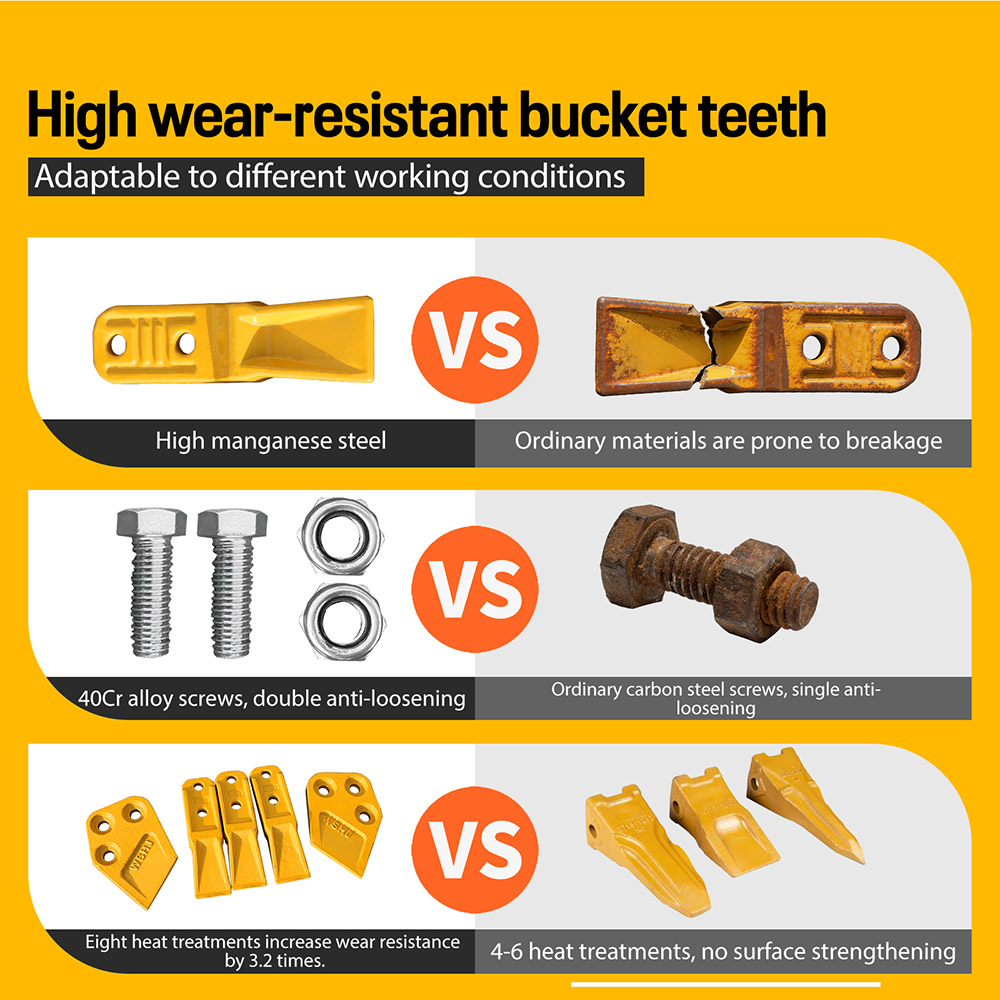

From a manufacturing perspective, this series of shovel teeth is not a typical product requiring only one or a small amount of heat treatment; rather, it undergoes up to eight heat treatment processes for strengthening.

This process achieves a more reasonable balance between surface hardness and internal toughness, resulting in superior wear resistance in practical use.

Comparison:

High-manganese steel shovel teeth:

Eight heat treatments

Significant surface strengthening

Wear resistance increased by approximately 3.2 times

More suitable for hard soil, gravel, and high-impact conditions

Ordinary material shovel teeth:

4–6 heat treatments

Insufficient surface strengthening

More prone to fracture at the main cutting tooth location

This difference in manufacturing process is particularly noticeable during long-term, high-intensity construction, directly impacting the frequency of shovel tooth replacement and overall construction costs.

The optimized tooth design allows the shovel teeth to cut into soil or crush hard materials more smoothly, helping to maintain a stable operating rhythm and reducing efficiency loss due to auxiliary tool wear.

Standardized size design makes installation and replacement easier.

Structurally, the shovel teeth adopt a standardized design in terms of size and hole positions, with strict control over hole spacing, diameter, and thickness.

The bolt-fixed installation method ensures a tight fit between the shovel teeth and the tooth base, preventing loosening under high loads and significantly reducing disassembly and assembly difficulty.

For overseas users, this means:

Faster on-site replacement speed

Lower labor maintenance costs

Less equipment downtime

Overseas warehouse stock support, shortening delivery and maintenance cycles

Currently, this batch of bucket teeth and side teeth accessories has been stocked in our overseas warehouse, supporting both complete machine shipments with orders and rapid supply of accessories individually. This local inventory model effectively shortens delivery cycles, helping customers quickly obtain necessary parts during peak equipment maintenance or construction periods, avoiding project delays due to accessory shortages.

Continuously Improving the Accessory System and Building Complete Operational Solutions

As one of the most basic and critical accessories for excavators, bucket teeth are an important component of our overseas warehouse accessory system. In the future, we will continue to expand the categories of our overseas warehouse inventory, focusing on commonly used accessories and wear parts for mini excavators, to provide customers with more complete and flexible localized support solutions.