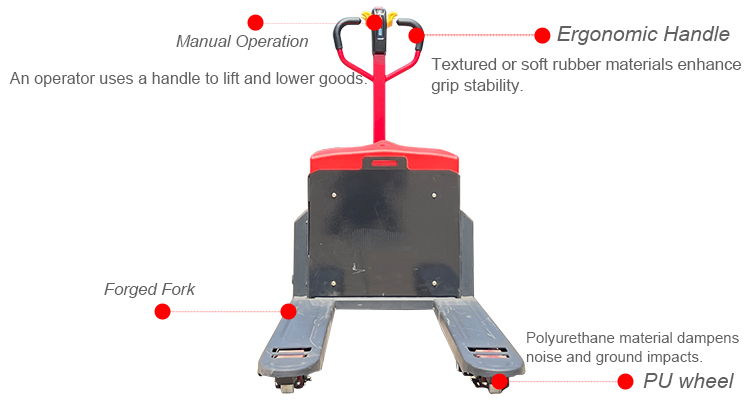

Manual forklift truck

As core equipment for short-distance cargo handling in modern warehousing and logistics, electric trucks, leveraging the advantages of electric technology, significantly outperform traditional manual trucks and some fuel-powered equipment in terms of efficiency, cost, and environmental adaptability. Their product advantages can be summarized in six core dimensions: user experience, operating costs, environmental adaptability, safety performance, operational efficiency, and ease of maintenance. Specifically, they are as follows:

1. Low operating threshold and improved labor costs

2. Low operating costs and significant long-term economic benefits

3. Strong environmental adaptability and compatibility with multiple scenarios

4. Comprehensive safety features reduce operational risks

5. Stable operating efficiency and battery life that meets daily needs

6. Easy maintenance and high equipment availability

Warehousing and logistics equipment used for short-distance cargo handling, loading and unloading, and stacking assistance is widely used in warehouses, workshops, supermarkets, logistics parks and other scenarios. Its core function is to replace the human operation of manual trucks and the high energy consumption mode of fuel trucks, achieving "efficient, low-cost, and low-threshold" cargo transportation.

1. Powertrain: Core is "Battery + Motor"

Batteries: The mainstream are lithium batteries (lightweight, fast-charging, long cycle life, suitable for high-frequency operations) and lead-acid batteries (low cost, simple maintenance, suitable for budget-constrained scenarios).

Motors: There are drive motors (control driving) and hydraulic motors (control fork lift). Power typically ranges from 0.5-3kW. The larger the load and the faster the travel speed, the higher the motor power required.

2. Control System: Core is the "integrated handle." This integrates a forward/reverse switch, speed control knob, fork lift button, and emergency stop button. Some high-end models include an LCD display (displaying battery level and fault codes).

Some models are equipped with "electronic power steering" to reduce steering effort and improve maneuverability. 3. Loading and Lifting System

Forks: Typically two manganese steel forks, customizable in length (commonly 1.1-1.5 meters) and adjustable in spacing (to accommodate different pallet sizes);

Hydraulic System: Consists of a hydraulic pump, cylinder, and hoses, controlling the fork lift speed (typically 0.1-0.3 m/s). Some models feature a high-limit stop to prevent damage from overtravel.

4. Braking System: Ensuring Operational Safety

The mainstream system is electromagnetic braking (automatically shuts off the brakes upon releasing the control handle to prevent rolling). Some models also feature a mechanical foot brake for parking.

Heavy-duty models (over 3 tons) feature dual-circuit braking for enhanced braking reliability.

5. Travel System

Tires: Available in solid rubber (wear-resistant, no risk of blowouts, suitable for flat surfaces) and polyurethane (quiet, non-slip, suitable for clean indoor environments).

Frame: Utilizes a welded steel structure with reinforced weight-bearing areas to ensure deformation when fully loaded.